Water quality is constantly variable. To produce demineralised water of a very high purity, it must undergo a process whereby the two main types of impurity are removed. These two types of impurity can loosely be defined as:

- Suspended Solids – such as finely divided solid matter that is too small to settle out of the water, and

- Dissolved Solids – which comprise of material that’s actually dissolved in the water itself.

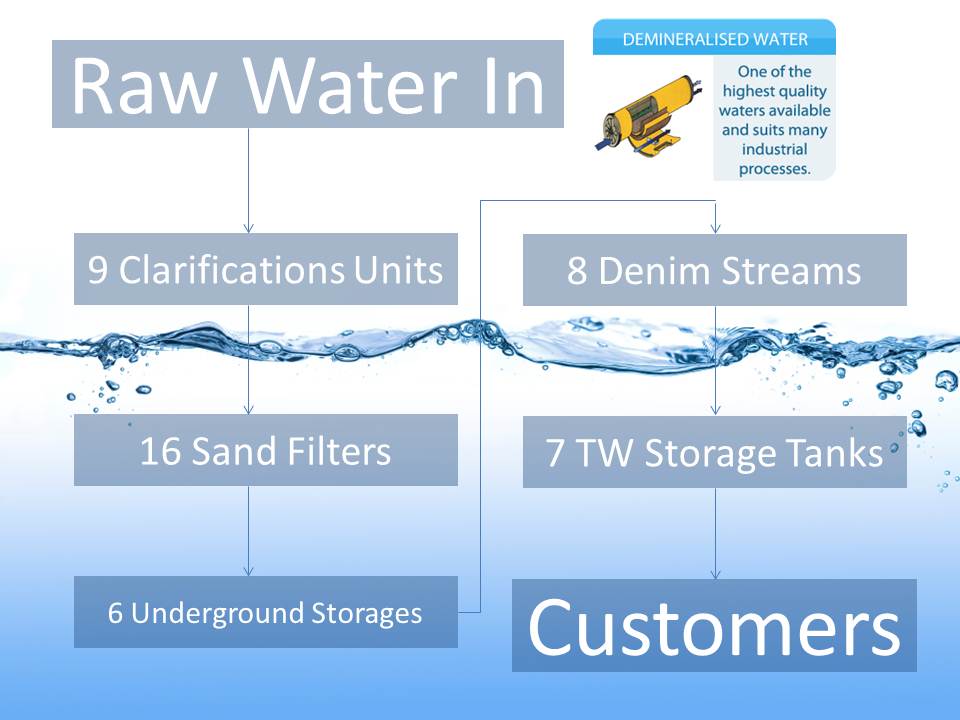

These two types of impurity can be reduced to virtually zero as a result of the two separate processes we employ. The first process if that of Clarification/Filtration, and the second is Demineralisation.

Clarification

Depending on the different types of impurities prior to Clarification/Filtration, the water can have a yellow/brown colouration. Colour variations can be attributed to such components as heavy rainfall and results from the presence of suspended organic matter and small particles of clay.

To carry out the Clarification process, we use Aluminium Sulphate, which is added to the water. Under the right conditions, the chemical acts as a coagulant and forms a flocculent precipitate in the water. This flocculent holds an electrostatic charge on its surface, which attracts the minute colour particles in the water.

Initially the size of the flocculent particles is very small and they behave similarly to the suspended particles in the water. But by converting the flocculent particles into larger and heavier pieces by attracting the minute colour particles, it then settles to the base of the clarifier units from where it is purged to drain as a loose sludge.

Filtration

During the Filtration process, the water passes through sand beds, which trap any particles that have been carried over from the previous stages. However it’s not as simple as just leaving the water to flow. If nothing were done, this Filtration would gradually choke up the sand and the flow would be restricted.

To avoid this, the sand if periodically air agitated and backwashed in each filter in turn. In this way, the sand can be returned in clean condition and prevent the build up of particles that would restrict the flow. The water used to clean the filters is collected and returned to the start of the Clarification process to reduce waste and costs.

The colourless water that leaves the filters is now known as Clarified Water.

Demineralisation

Once the Clarified Water has been produced, it’s stored in a series of underground tanks from where it is pumped to the Demineralisation Plants for the removal of the dissolved solids. These dissolved solids consist of materials that have been absorbed during the water’s passage through the ground towards the river, as well as run-off from land in the catchment area. The dissolved solids fall into two distinct categories both known as Ions: there are POSITIVELY charged cations, and NEGATIVELY charged anions.

The principle of Ion Exchange is to remove the cations from the water and replace them with positively charge hydrogen ions, and swap anions for negatively charged hydroxyl ions. This exchange is carried out using specially manufactured structures known as Ion Exchange Resins.

During a pass through these resins, the vast majority of cations and anions are removed from the water. This process depletes the available hydrogen and hydroxyl ions, and the process must be halted so that the resins may be refreshed.

Having gone through the Ion Exchange Resins, however, the water still does not meet the stringent specifications required to meet the standard of our demineralised water. To achieve the final polishing of the water, it is passed through a final resin bed that contains a mixture of the cation and anion resin, which is known as a Mixed Bed.

On leaving the Mixed Beds, the demineralised water is up to scratch and passes to the storage system, from which it is dispersed to the customers.

Unit B, 2 Endeavour Way London, LO, SW19 8UH United Kingdom

contact@thedistilledwatercompany.com • 0845 500 5440